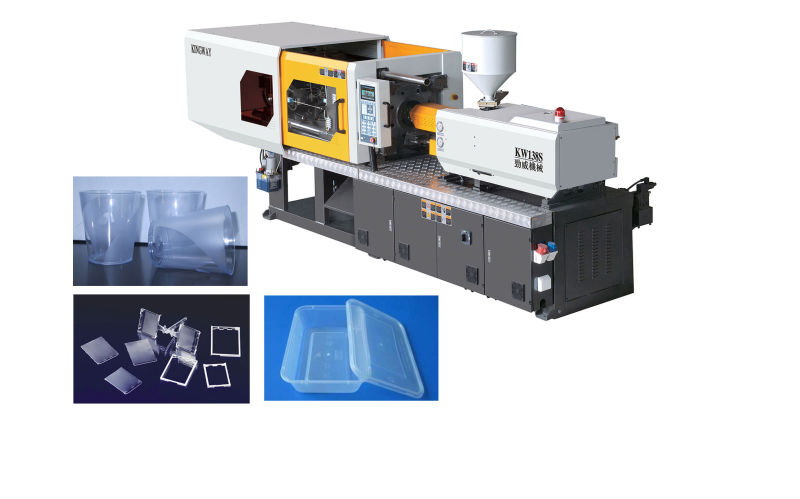

Servo Energy Saving Plastic Injection Machine (100Ton)

Basic Info

Model No.: KW100S

Product Description

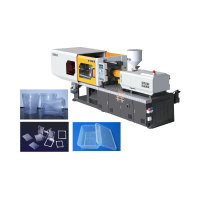

Model NO.: KW100S Structure: Horizontal Plasticizing Way: Screw Type Automation: Automatic Clamp Force: 100ton: Shot Weight: 160g Transport Package: Plastic Film HS Code: 8477101090 Type: PP, PE, PC, PA, ABS, Pet, PVC etc. Plastic Type: Thermoplastic Clamping Way: Hydraulic & Mechanical Computerized: Computerized Trademark: Kingway Origin: Ningbo China Servo Energy Saving Injection Molding Machine Servo energy saving injection molding machine output power changes with the loading changing. There's no extra waste of power. The motor doesn't work while cooling, electricity consumption is 0. As compared with the tradition Injection Molding Machine, the servo machine can save electricity 20%-80% that brings you excellent profit.

-Excellent energy saving As compared with the traditional fixed pump injection molding machine, it saves energy 20%-80% under the same working condition.

-Excellent injection molding stability The pressure and flow of servo drive system applies closed-loop control, as compared with the traditional injection molding machine, it greatly increases repeatability precision of injection molding.

-Fast response Fast response servo drive, the start time faster than that of the traditional injection molding machine by 50%.

-Environmental friendly The complete machine runs under low noisy, low speed operation and quite.

-Constant oil temperature The servo motor output hydraulic oil according to proportion to avoid extra heat. Even the hydraulic oil need not to be cooled to realize excellent water saving

Contact us if you need more details on Servo Energy Saving Injection Molding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Injection Molding Machine、Injection Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

-Excellent energy saving As compared with the traditional fixed pump injection molding machine, it saves energy 20%-80% under the same working condition.

-Excellent injection molding stability The pressure and flow of servo drive system applies closed-loop control, as compared with the traditional injection molding machine, it greatly increases repeatability precision of injection molding.

-Fast response Fast response servo drive, the start time faster than that of the traditional injection molding machine by 50%.

-Environmental friendly The complete machine runs under low noisy, low speed operation and quite.

-Constant oil temperature The servo motor output hydraulic oil according to proportion to avoid extra heat. Even the hydraulic oil need not to be cooled to realize excellent water saving

| Ningbo Kingway Machinery Co., Ltd | |||

| Technical parameter | |||

| Item | Unit Model | KW100 | |

| Injection unit | |||

| Screw type | A | B | |

| Screw diameter | mm | 35 | 38 |

| Shot volume(theoritical) | cm 3 | 154 | 181 |

| Injection weight (PS) | g | 138 | 160 |

| Injection rate | g/s | 75 | 78 |

| Injection pressure | Mpa | 149 | 126 |

| Screw rotation speed | r.p.m | 190 | |

| Clamping unit | |||

| Clamping force | KN | 1000 | |

| Open stroke | mm | 290 | |

| Space between tie bars(W*H) | mm | 355*315 | |

| Max. mould height | mm | 350 | |

| Min. mould height | mm | 150 | |

| Ejector stroke | mm | 70 | |

| Ejector force | KN | 27 | |

| Others | |||

| Max. Pump pressure | Mpa | 14 | |

| Pump motor power | KW | 9.5 | |

| Heating power | KW | 6.2 | |

| Machine dimension(L*W*H) | m | 3.5*1.25*1.7 | |

| Machine weight | t | 2.7 | |

Product Categories : Servo Energy Saving Injection Molding Machine

Premium Related Products

Other Products

Hot Products

Honeycle Cylinder Dehumidification DryerHopper DryerServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P268Servo Energy Saving Plastic Injection Machine (100Ton)Dual-Color Injection Molding MachineBMC Thermosetting Injection Molding Machine96t Plastic Injection Moulding Machine Hi-G96198t High Performance Injection Moulding Machinebucket plastic injection molding machine with high speedplastic chair injection molding machine with energy savingbucket plastic injection molding machine Made in Chinainjection plastic molding machine 24 hours online for salePVC pipe fitting plastic injection moulding machine for salewater bucket, plastic chair injection molding machine price in Ningbo supplier over ten years5 gallon preforms injection molding machine supplier 24 hours on-line