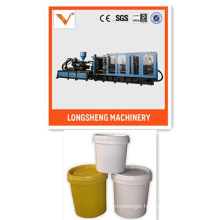

Beer Box Injection Moulding Machine

Basic Info

Model No.: LSF-718

Product Description

Model NO.: LSF-718 Structure: Horizontal Plasticizing Way: Screw Type Automation: Automatic Certification: CE, ISO9001:2008 Toggle Stroke: 930mm Space Between Tie Bars: 910X910mm Min Mold Height: 380mm Heater Power: 59.5kw Machine Weight: 37t Specification: SGS HS Code: 8477101090 Type: Plastic Injection Molding Plastic Type: Thermoplastic Clamping Way: Hydraulic Computerized: Computerized Clamp Force: 7180kn Injection Weigh: 3162g Max. Mold Height: 950mm Max. Pump Pressure: 16MPa Machine Dimension(L*W*H): 10.08X2.4X3m Trademark: LONG SHENG Origin: Changzhou City, Jiangsu Province, China Beer box Injection Moulding Machine To make a beer boxes ,it takes about 70 seconds , so in one hour can get 50-55 pcs of beer crates . In one day (if based onBeer box Injection moulding Machine 8 hours )can get :440pcs of crates , below is machine technical data ,

LONGSHENG Machine Advantage:

1)Guarnateed for two years

2) Offer Injection Machine Operation&trainning Vedio

3) Have SGS certificate

4) T-Slot Platen

5)Machine weight much more than most of factory

6)Machine base use rectangular tube, more strong

7)Four PCS safe door are moveable, maintain the machine more convenience

8)Hydraulic Tank is moveable, more easy to clean the tank when needed

9)Heating band is made by ceramics, not steel sheet. Can work more long time;

10)Prepared more spare parts for customer as below:

2PCS nozzle; 1 set tool box; 3PCS heating band; 1 set mold clamp; 1 container lubricate oil; 1 PC oil filter; 2 PCS switch; 1 set spanner; Seal circle: 3PCS

11) Injection Machine computer with USB connect Point, you can move all mould settings parameter on your desktop computer

Packaging & Delivery

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and with a number of peripheral interfaces.

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

CLAMPING SYSTEM

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

CLAMPING SYSTEM

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

Contact us if you need more details on Beer Box Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Beer Box Plastic Injection Moulding Mac、Beer Box Injection Molding Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

| INJECTION UNIT | Unit | LSF-718 | |||

| A | B | C | |||

| Screw Diameter | Mm | 90 | 100 | 110 | |

| Screw L/D Ratio | L/D | 22 | 19.8 | 18 | |

| Short Size | Cm3 | 2815 | 3475 | 4205 | |

| Injection weight | g | 2560 | 3162 | 3826 | |

| Injection Rate | g/s | 692 | 855 | 1034 | |

| Plasticizing Capacity | g/s | 86 | 112 | 138 | |

| Injection Pressure | Mpa | 176 | 142 | 117 | |

| Screw Speed | Rpm | 0-135 | |||

| Screw Stroke | mm | 442 | |||

| CLAMPING UNIT | Clamp Force | KN | 7180 | ||

| Space Between Tie Bars | mm | 910X910 | |||

| Toggle Stroke | mm | 930 | |||

| Max. Mold Height | mm | 950 | |||

| Min Mold Height | mm | 380 | |||

| Ejector Stroke | mm | 260 | |||

| Ejector Tonnage | KN | 181 | |||

| OTHERS | Max. pump Pressure | Mpa | 16 | ||

| Pump motor powder | Kw | 30+30 | |||

| Heater Power | Kw | 59.5 | |||

| Machine Dimension(L*W*H) | M | 10.08X2.4X3 | |||

| Oil tank capacity (L) | L | 1350 | |||

| Machine Weight | T | 37 | |||

LONGSHENG Machine Advantage:

1)Guarnateed for two years

2) Offer Injection Machine Operation&trainning Vedio

3) Have SGS certificate

4) T-Slot Platen

5)Machine weight much more than most of factory

6)Machine base use rectangular tube, more strong

7)Four PCS safe door are moveable, maintain the machine more convenience

8)Hydraulic Tank is moveable, more easy to clean the tank when needed

9)Heating band is made by ceramics, not steel sheet. Can work more long time;

10)Prepared more spare parts for customer as below:

2PCS nozzle; 1 set tool box; 3PCS heating band; 1 set mold clamp; 1 container lubricate oil; 1 PC oil filter; 2 PCS switch; 1 set spanner; Seal circle: 3PCS

11) Injection Machine computer with USB connect Point, you can move all mould settings parameter on your desktop computer

Packaging & Delivery

| Packaging Detail: | Plastic Injection Molding Machine in wooden pallet |

| Delivery Detail: | 15-45days after receiving TT deposit or L/C at sight |

CONTROL SYSTEM

All-digital control system uses dedicated controller, multiple CPU processing division,

a multi-functional automatic fault detection, alarm system, certificates 99 mold of

processing procedures, with remote control interface. System is of high stability and

responsiveness. System uses color LCD, man made interface for easy operation and with a number of peripheral interfaces.

HYDRAULIC SYSTEM

Advanced hydraulic system design, through proportional control of pressure, flow achieves rapid multi-level pressure, speed switching, the system configuration is reasonable, stable and reliable. The noise is less than 75 dB. The medium and large machine adopts a two way cartridge inserted valve system to improve the system of flow and speed of response, and makes the whole machine reach the best performance.

CLAMPING SYSTEM

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

CLAMPING SYSTEM

- Security doors fitted with hydraulic, mechanical and electrical interlocking triple safety device. When the safety door is open, the machine cannot clamp.

- Low pressure mold protection device to prevent damage to platen.

- Plywood, frame, the bridge, and the template attached structure, the finite element analysis.

- Hydraulic ejector, adjustable stroke, and top speed of ejector in and out, for multiple actions.

- Flexible tie bars nut eliminates fatigue fracture; assure the working life of tie bars

- Automatic adjustment. The replacement of different mold, the parameters set by clamping force to achieve the automatic adjustment.

- High-precision electronic detection device, multi-stage control of opening stoke, speed and location, location accuracy.

Contact us if you need more details on Beer Box Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Beer Box Plastic Injection Moulding Mac、Beer Box Injection Molding Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : synchronized injection molding machine

Other Products

Hot Products

Honeycle Cylinder Dehumidification DryerHopper DryerServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P268Servo Energy Saving Plastic Injection Machine (100Ton)Dual-Color Injection Molding MachineBMC Thermosetting Injection Molding Machine96t Plastic Injection Moulding Machine Hi-G96198t High Performance Injection Moulding Machinebucket plastic injection molding machine with high speedplastic chair injection molding machine with energy savingbucket plastic injection molding machine Made in Chinainjection plastic molding machine 24 hours online for salePVC pipe fitting plastic injection moulding machine for salewater bucket, plastic chair injection molding machine price in Ningbo supplier over ten years5 gallon preforms injection molding machine supplier 24 hours on-line