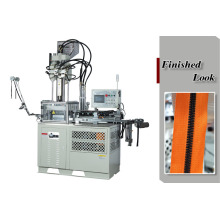

300ton Injection Molding Machine with Servo Motor

Basic Info

Model No.: LSF-308

Product Description

Model NO.: LSF-308 Structure: Horizontal Plasticizing Way: Screw Type Automation: Automatic Certification: CE, ISO9001:2008, SGS Tie Bar Sizes: 630*630mm Injection Rate: 177-239g/S Machine Sizes: 6.15*1.56*2m Specification: CE, SGS, ISO9001 HS Code: 8477101090 Type: Preform Injection Plastic Type: Thermosetting Clamping Way: Hydraulic & Mechanical Computerized: Computerized Shot Weight: 830-1136gr Mold Height: 200-630mm Injection Pressure: 193-412MPa Trademark: LONGSHUN Origin: Changzhou Jiangsu China 300ton Injection Molding Machine with servo motor

Plastic Injection Machines we build clamping force from 680 to 8800KN, shot weight from 83 to 4390gr, which can meet all kinds of plastic products production requirements.

Equiped with servo motor, which energy saving by 60% in average ,with longer working life (low oil temperature),low noise ,high precision (close looped system ).

Welcome contact us for more details and professional services.

Technical specifications;

Features:

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

Servo Controller Part: 1. High Precise Control The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is Contact us if you need more details on Plastic Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Injection、Plastic Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Plastic Injection Machines we build clamping force from 680 to 8800KN, shot weight from 83 to 4390gr, which can meet all kinds of plastic products production requirements.

Equiped with servo motor, which energy saving by 60% in average ,with longer working life (low oil temperature),low noise ,high precision (close looped system ).

Welcome contact us for more details and professional services.

Technical specifications;

| INJECTION UNIT | Unit | LSF-308 | |||

| A | B | C | |||

| Screw Diameter | Mm | 60 | 67 | 70 | |

| Screw L/D Ratio | L/D | 21.6 | 19.8 | 18.6 | |

| Short Size | Cm3 | 918 | 1145 | 1250 | |

| Injection weight | G | 830 | 1030 | 1136 | |

| Injection Rate | g/s | 177 | 206 | 239 | |

| Plasticizing capacity | g/s | 41 | 49 | 57 | |

| Injection Pressure | Mpa | 193 | 158 | 142 | |

| Screw Speed | Rpm | 0-185 | |||

| CLAMPING UNIT | Clamp Force | KN | 3080 | ||

| Space Between Tie Bars | mm | 630*630 | |||

| Toggle Stroke | mm | 590 | |||

| Max. Mold Height | mm | 630 | |||

| Min. Mold Height | mm | 200 | |||

| Ejector Stroke | mm | 160 | |||

| Ejector Tonnage | KN | 62 | |||

| Ejector Number | P | 9 | |||

| OTHERS | Max. pump Pressure | Mpa | 16 | ||

| Pump motor powder | Kw | 30 | |||

| Heater Power | Kw | 18 | |||

| Machine Dimension(L*W*H) | M | 6.15*1.56*2 | |||

| Machine Weight | T | 10.2 | |||

Features:

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

Servo Controller Part: 1. High Precise Control The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is Contact us if you need more details on Plastic Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Injection、Plastic Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : energy saving injection molding machine

Premium Related Products

Other Products

Hot Products

Honeycle Cylinder Dehumidification DryerHopper DryerServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P268Servo Energy Saving Plastic Injection Machine (100Ton)Dual-Color Injection Molding MachineBMC Thermosetting Injection Molding Machine96t Plastic Injection Moulding Machine Hi-G96198t High Performance Injection Moulding Machinebucket plastic injection molding machine with high speedplastic chair injection molding machine with energy savingbucket plastic injection molding machine Made in Chinainjection plastic molding machine 24 hours online for salePVC pipe fitting plastic injection moulding machine for salewater bucket, plastic chair injection molding machine price in Ningbo supplier over ten years5 gallon preforms injection molding machine supplier 24 hours on-line